Authors: Rao Desineni, Eugene Tuv

Semiconductor manufacturing comprises many steps—process, measurement, shipping, accounting, etc. Data is generated at each of the n steps that a silicon wafer or die must traverse before revenue is realized. The purpose of every manufacturing AI application must include at least one of the following:

- Detect a problem at step n.

- If a problem is detected at step n, rapidly find its root cause using the data collected at the previous n-i steps, where 0< i ≥ n.

- Predict the outcome at step n using the data from the

previous n-i steps, where 0< i ≥ n, and devise control

methods to optimize outcomes at step n.

Intel has been developing and using AI-enabling methods — machine learning, deep learning, computer vision and image processing, advanced multivariate statistics, operations research, and others—in various aspects of IC technology development (TD) and high-volume manufacturing (HVM) for almost two decades. The complexity of TD and the scale of HVM forced us to steadily replace rule-based systems with learning-based systems (aka AI) for use cases where it made sense. And the journey continues.

Deploying AI at Scale in Intel’s Manufacturing Environment

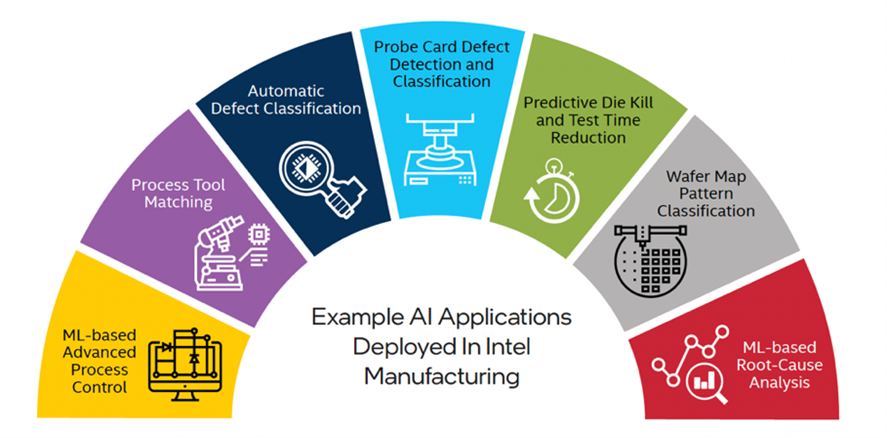

Some of the AI applications deployed in production in Intel factories include:

- Inline defect detection

- Tool/fleet/fab matching

- Multivariate process control

- Automated wafer map pattern detection and classification

- Fast root-cause analysis (RCA)

- Detecting outliers at sort test for both test time reduction and quality improvements in downstream shipped products

The adoption of AI in Intel's factories includes various applications.

Each of these applications fit the n-i, n problem statement. For example,

RCA: Data from n-i steps is used to find the root cause for the abnormality observed at step n.

Machine learning for Advanced Process Control (APC): Data from n-i steps is used to control the process at step n.

Predictive Die Kill and Test Reduction: Machine-learning models are built using data from n-i steps to predict failures at some downstream step n.

Automatic Defect Classification (ADC): Applications are devised to detect anomalies and quantify baseline non-systematic defects at a given step n.

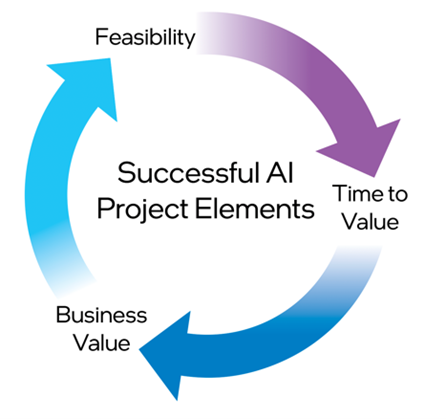

AI is poised to bring transformative changes to semiconductor manufacturing. We have been using a variety of AI solutions in Intel factories and have experienced their value in terms of yield, cost, and productivity gains. AI techniques offer more precise results, especially when compared to work performed by a less experienced engineer. However, AI is not magic. In each case, after the problem statement is first clearly understood, the AI algorithms need to be selected, adopted, or developed from scratch by machine-learning experts. Proof-of-Concept solutions need to be extensively validated by users and the perfected algorithms need to be integrated into factory automation systems via DevOps. Also, while we generate hundreds of petabytes of data, it is critical to apply AI to those use cases that can provide substantial business value, practical feasibility, and the quickest time to value.

Our AI project prioritization process consists of evaluating feasibility, time to value, and

business value.

We expect the current AI spring to continue at least into the next decade. In semiconductor manufacturing as a whole, we are seeing growing awareness of AI across OEM suppliers, electronic design automation (EDA) vendors, data infrastructure providers, and our competitors. Just as the Industrial Revolution took a while to mature, the vision of “AI everywhere” will take time to become a reality. We are certain it will happen much faster than the former, but it will take some enterprise-wide cultural changes to supplement the technical solutions and make AI ubiquitous.

Intel manufacturing is on a path to implement AI solutions where they provide business value. We continually modernize our automation systems, data infrastructure, and most importantly, organizational culture, knowing that the greatest advantage comes when humans and machines work together.

Read the white paper to learn more.

Rao Desineni is Senior Director of Data Analytics in the Manufacturing, Supply Chain & Operations organization at Intel Hillsboro, Oregon. He leads a team of data scientists and software engineers responsible for developing and deploying at-scale semiconductor manufacturing analytics solutions. With broad expertise in semiconductor technology development, design enablement, design automation, manufacturing and test, Rao is passionate about bringing Applied Intelligence – AI solutions deployed at-scale – into all aspects of semiconductor design & manufacturing. Previously, he spent 6 years each at GLOBALFOUNDRIES and IBM. Rao received his Ph.D. in ECE from Carnegie Mellon University, has published over 30 conference and journal papers, and holds eight U.S. patents, all in semiconductor manufacturing and test.

Rao Desineni is Senior Director of Data Analytics in the Manufacturing, Supply Chain & Operations organization at Intel Hillsboro, Oregon. He leads a team of data scientists and software engineers responsible for developing and deploying at-scale semiconductor manufacturing analytics solutions. With broad expertise in semiconductor technology development, design enablement, design automation, manufacturing and test, Rao is passionate about bringing Applied Intelligence – AI solutions deployed at-scale – into all aspects of semiconductor design & manufacturing. Previously, he spent 6 years each at GLOBALFOUNDRIES and IBM. Rao received his Ph.D. in ECE from Carnegie Mellon University, has published over 30 conference and journal papers, and holds eight U.S. patents, all in semiconductor manufacturing and test.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.